How RFID technology works

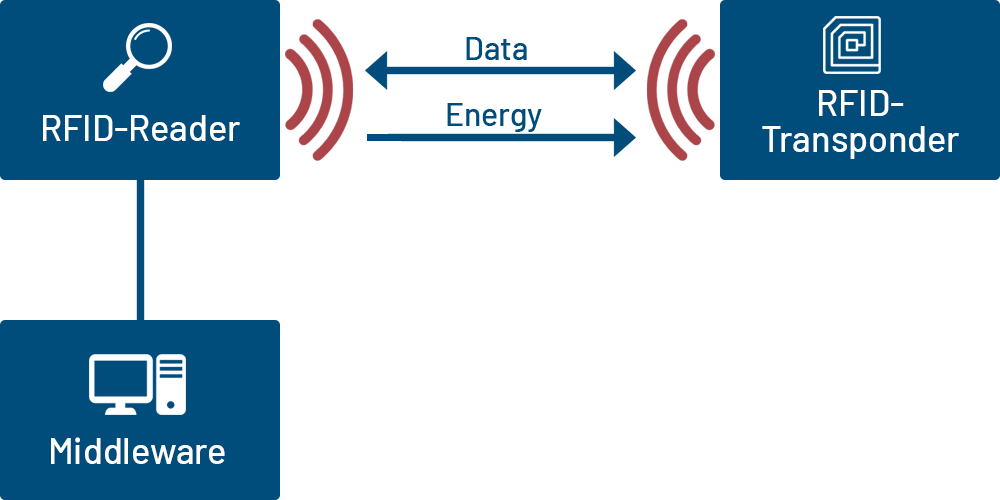

An RFID system consists of an RFID reader and an RFID transponder. The reader emits an alternating electromagnetic field. The energy of this magnetic wave can be absorbed by the antenna of one or more nearby RFID transponders and is used to supply energy and exchange data.

RFID technology is divided into the following three areas

- LF (Low Frequency) 125kHz (FDX) und 134kHz (HDX)

- HF (High Frequency) und NFC (Near Field Communication) 13.56 MHz

- UHF (Ultra High Frequency) 868 MHz

| Frequency range | Low Frequency (LF) | High Frequency (HF/NFC) | Ultra High Frequency (UHF) |

|---|---|---|---|

| Ranges | up to 10 cm | up to 50 cm | up to 15 Meter |

| ISO standard | ISO 14223 | ISO 1443 / 15693 | EPC Global Gen2 |

| Applications | Animal identification, waste collection | Ticketing, payment systems | Logistics, retail |

RFID-Chips

The chip or IC contains the actual function of the transponder. The chip provides computing power, memory and, in the case of special transponders, extended functions (e.g. encryption functions). The chip is typically pre-programmed with a tag ID (TID), a unique serial number (from the chip manufacturer). Transponders in the UHF range have an EPC memory. This contains the electronic product code (EPC). Furthermore, many chips have additional memory (user memory) that can be freely written to. Passive RFID chips can only work if they are supplied with power via the antenna.

The right choice of RFID chip is not only dependent on the desired transmission frequency.

Depending on the application, the following parameters must be taken into account:

- User memory

- Data retention

- Operating temp range

Here is an overview of the most common RFID chip manufacturers and types:

- LLF Chips 12 5 kHz - FDX

- NXP HITAG S256, HITAG S2048, HITAG 2 und weitere

- EM Microelectronic EM4095, EM4097, EM4200, EM4205/4305, EM4450

- LF Chips 134,2 kHz HDX

- Silicon Craft SIC 279

- HF-Chips 13. 56 MHz

- NXP ICODE DNA, ICODE SLIX 2, ICODE SLIX, ICODE SLIX-L, ICODE-SLIX-S, ICODE ILT

- EM Microelectronic EM4033, EM4096, EM4133, EM4233, EM4233SLIC, EM4237, EM4237SLIC/SLIX, EM4333, EM4423, EM4830, NF4

- NFC-Chips

- NXP NTAG 210 Micro, NTAG 210, NTAG 212, NTAG 213, NTAG 215, NTAG 216, NTAG I²C, NTAG216F, NTAG213F

- Dual Tech-Chips (NFC/UHF)

- EM4423 - ISO14443/RAIN UHF

- EM4425 - ISO15693/RAIN UHF

- UHF-Chips:

Impinj Monza 4, 5, R6, R6-P, S6-C

NXP U-Code family (Ucode7, Ucode8, DNA)

EM Microelectronic EM4123, EM4124, EM4126, EM4298, EM4325, EM4423

Areas of application for RFID

Identification using radio waves (Radio Frequency Identification) is contactless and is used in numerous applications:

- Mass transportation

- Access control

- ID and authentication

- Events

- Cashless payments

- Ticketing

- Counterfeit protection

- Blockchain management

Why is RFID technology used?

The following three technologies are generally used to label products:

- Barcode

- QR Code

- RFID transponder

The advantage of barcodes and QR codes over RFID marking is that, although they are inexpensive, visual contact - visual inspection - is always required between the reader and the marking when reading. RFID marking does not require a visual connection between the transponder and reader and also offers the option of reading several objects at the same time with one reading cycle.

Further advantages of using RFID

- Each chip has a serial number, the so-called UID (unique identifier). This globally unique UID is assigned by the chip manufacturer and cannot be manipulated.

- A writable memory, known as the user memory, can be used to write additional data to the chip, which contributes to process optimization and can also be used for service and maintenance intervals.

- Special chips that allow data to be encrypted can be used for blockchain, authentication and anti-counterfeiting applications.

- In the logistics sector, the possibility of bulk reading in particular, whereby several objects can be recorded with one read cycle, offers the great advantage of simplifying and accelerating logistics processes.

RFID application areas

Production and logistics

In production, RFID transponders are either attached to pallets, trays, packaging or directly to individual parts. Individual parts can be accessories or small electronic units, for example, which are recorded by RFID at various points during the production process, creating traceability and transparency (track and trace, batch numbers, expiry date).

In the area of logistics and warehousing, inventory plays a particularly important role. The transponders are automatically recorded when goods are received or dispatched. This means that the exact stock level can be called up in the respective ERP system at any time and a corresponding message can be sent when a certain low level is reached.

Smart fashion logistics with UHF/NFC

RFID labels are attached to the items during production so that each process step can be precisely documented and traced from production. With the RFID inlays attached to the labels or shoe soles, every single step from production to sale can be tracked.

Wherever parcels, pallets or containers with goods arrive, are forwarded or dispatched, RFID technology prevents picking errors. Incoming and outgoing goods are recorded with mobile or stationary readers, which makes visual inspection unnecessary and the quantity can be checked automatically.

n the stores, RFID is used to read and record goods in the ERP system in a matter of seconds. Incoming goods are thus recorded 100% without any effort and can be reordered directly by writing them off when they are sold. An inventory can be initiated at the touch of a button.

If the customer enters the changing room with an item of clothing equipped with RFID, it can be read and show the customer on a display which sizes, colors, etc. are available. The staff can bring the appropriate garments to the changing room.

High-quality textiles and shoes can also be read by cell phone at any time by attaching a dual-frequency inlay (UHF/NFC) in order to determine the authenticity of the goods. In this case, the read data records are compared online with the manufacturer's database.

This type of transparent process can lead to an increase in sales and a long-term reduction in costs, as well as a reduction in warehousing costs thanks to quick availability checks and increased security.

RFID in customer and credit cards

The use of RFID technology in plastic cards has been widespread for years, especially in locking systems such as hotel doors, etc. The card is virtually wear-free, reusable and enables convenient handling. More complex NFC chips are used for contactless payment, which are read by a POS terminal and make it unnecessary to enter the pin for amounts below a certain limit.

Keyless-Entry & Go in der Autoindustrie

As soon as the driver comes within a few centimetres of the vehicle equipped with Keyless GO, the system is woken from “sleep mode” with the help of an always active on-board capacitive or optical sensor and a coded request signal with an LF frequency of 125 or 130 kHz is transmitted via several antennas distributed throughout the vehicle. The on-board system then switches to a receive mode in the UHF range and waits for confirmation. If the key with the RFID transponder is within range, it receives the signal on 125 kHz, decodes it and actively transmits it again, powered by a battery, with a new coding in the UHF frequency band. In the vehicle, a control unit decodes it again.

Da das Keyless-Go-Steuergerät beide Codiertabellen kennt, kann es die eigene ursprüngliche Aussendung mit dem gerade empfangenen Signal vergleichen. Gibt es innerhalb einer definierten Zeit keine korrekte Antwort, passiert nichts und das System schaltet wieder auf Standby. Ein Ziehen des Türgriffes hat keine Wirkung, da der Zustand des Türschlosses vom Keyless-Go-System nicht verändert wurde. Stimmen jedoch beide Codes überein, bewirkt das eine Authentisierung, das bordseitige System gibt das Schloss frei, und ein Ziehen des Griffes entriegelt die Tür. Alternativ kann das Fahrzeug auch mit der Fernbedienung geöffnet werden. Zudem gibt es einen mechanischen Notschlüssel, mit dem sich zumindest die Fahrertür öffnen lässt. Ein Fahrzeugschlüssel eines Keyless-Go-Fahrzeugs besteht daher aus dem mechanischen Schlüssel, der batteriegespeisten Fernbedienung und einem RFID-Transponder sowie einer Batterie.

RFID in industrial production

In the factory of the future, the information stored on the transponder controls the production process. With the help of RFID technology, bidirectional communication with the respective workpiece is possible at any desired point in the production chain. This means that the workpiece can provide information at any time about the next step to be taken.

RFID also considerably simplifies goods receipt, as the readers can record several hundred transponders within a few moments and book them into the ERP system. At goods issue, the parts are recorded again and booked out again, thus ensuring maximum transparency in the value chain.

RFID in pharmacy and healthcare

In the field of pharmaceuticals, such as blood bags, RFID is used to monitor quality and ensure documentation security. In addition, a blood bag equipped with RFID can be easily identified and localized. The use of RFID is intended to protect against counterfeit drugs and improve the traceability of pharmaceutical products. RFID labels with a tamper loop can make tampering with the packaging recognizable.

In care facilities, patients can be identified and localized using RFID wristbands. The chip contains an individual patient number, under which the patient data is stored on a server. The attending physicians can read the patient number using a mobile reader and then view all the data on the server via a computer. In some care facilities, RFID wristbands are used to restrict access to certain areas for certain groups of people. This is primarily intended to ensure the safety of people suffering from dementia or disorientation. For example, it can prevent a dementia patient from leaving the building without the knowledge of care staff.

Animal identification with RFID

A few years ago, the identification of dogs and cats with an RFID transponder in the neck area became mandatory for pets. This is a so-called low-frequency glass transponder that can be used to identify the animal if it is lost.

In the livestock sector, stock and logistics are controlled via RFID. Cattle in particular are identified either by a so-called bolus in the stomach or with an ear tag. RFID can also be used to control the opening of certain gates and track how often the animal has come to feed.

RFID in libraries and bookshops

In most libraries, books have been labeled with RFID tags for a long time now, which makes it easy to check in and out and access the stock at any time. A customer card and corresponding system can significantly reduce the number of staff required.

Trade and logistics

With the introduction of “intelligent shelves”, RFID also enables more efficient shelf management. This optimizes the filling of shelves both in a warehouse and in a salesroom. RFID data provides insight into which goods/stock items need to be replenished on which shelves. If a product is missing from a shelf, this information is passed on to the central system so that it can be reordered as required. Goods assigned to the wrong shelves are also identified. The RFID system helps to ensure that information about the quality of goods is always up to date. Based on this data, goods that are close to their best-before date are quickly sold out and removed from the shelves shortly before the date expires. Furthermore, RFID technologies make it possible to calculate the total price by recording products in the shopping basket in which a reader is integrated. Only the payment process takes place in the checkout area, which shortens waiting times.

RFID in waste management

For some years now, local authorities have been equipping waste garbage cans with FDX or HDX transponders. This is read by a reader on the truck each time the bin is emptied. Depending on the system used, the bin can also be weighed and the customer receives an invoice based on the number of empties and the weight of the contents.

Counterfeit protection with RFID

The trend towards increasingly complex technologies does not make counterfeiting impossible, but it does make the work of counterfeiters considerably more difficult. Successful protection against counterfeiting is still not 100% achievable. However, if the hurdles are set very high and counterfeiting involves a great deal of effort for the counterfeiter, this can certainly serve as a deterrent.

In many cases, only elaborate packaging can be used for labeling (medicines, food). However, counterfeit products are also offered in their original packaging, so that different combinations can be found: Original products in original packaging - counterfeit products in original packaging - counterfeit products in counterfeit packaging.

The latest generations of RFID chips offer the possibility of encrypting data and so-called “block chain management”, which enables the data on the transponder to be compared with the data in a database at any time using a reader connected to the Internet, making it possible to verify authenticity.

RFID - tickets and payment systems

RFID tickets are increasingly being used in access systems for public transport, amusement parks, ski resorts, metros and municipal transport companies and are revolutionizing access systems in public transport. Due to the contactless identification and user-friendliness, more and more transportation companies are relying on RFID technology.

These systems can either be operated with RFID cards, but now more frequently with RFID tickets, which are supplied on continuous rolls or in fanfold format and are issued individually at ticket machines or at the counter. These are adapted to the application and encoded accordingly before delivery to the respective customer.

RFID in baggage handling at the airport

The international airline association Iata is obliging its members to use RFID chips for baggage. According to Iata, this was decided at the General Assembly in Seoul. The technology is intended to prevent errors in baggage handling. In addition, lost luggage should be found more quickly and thus returned to its owners more quickly.

The aim is to place an RFID transponder in a predefined position on each new suitcase during production. If an international agreement is reached to use the new dual-frequency technology here, the UHF part can be used for logistics on the conveyor belt and the tags on lost suitcases can be read at any time using a mobile phone.